Expanded Ecosystem Associate Member Spotlight: IS4S

We recently spoke to Sostenes Perez from NextFlex’s first Expanded Ecosystem Associate Member, Integrated Solutions for Systems, Inc. (IS4S).

Question: Sos, can you tell us about your role at IS4S and the focus of your organization?

Answer: With Integrated Solutions for Systems, Inc. (IS4S) I am a Research and Development Engineer currently managing the advancement of additively manufactured energetic material. IS4S is a small business that provides a wide range of engineering and management solutions to government, military, and commercial customers. Founded in 2008, IS4S specializes in PNT, missile system engineering, energetic research and development, vehicle electronics, additive manufacturing, and other innovative technologies. Our mission is to solve important problems for our customers in an environment where doing the right thing is more important than profit, and where our company is fully owned and operated by ethical, motivated employees.

Q: Your organization is new to the NextFlex ecosystem. What drew you to the hybrid electronics manufacturing community?

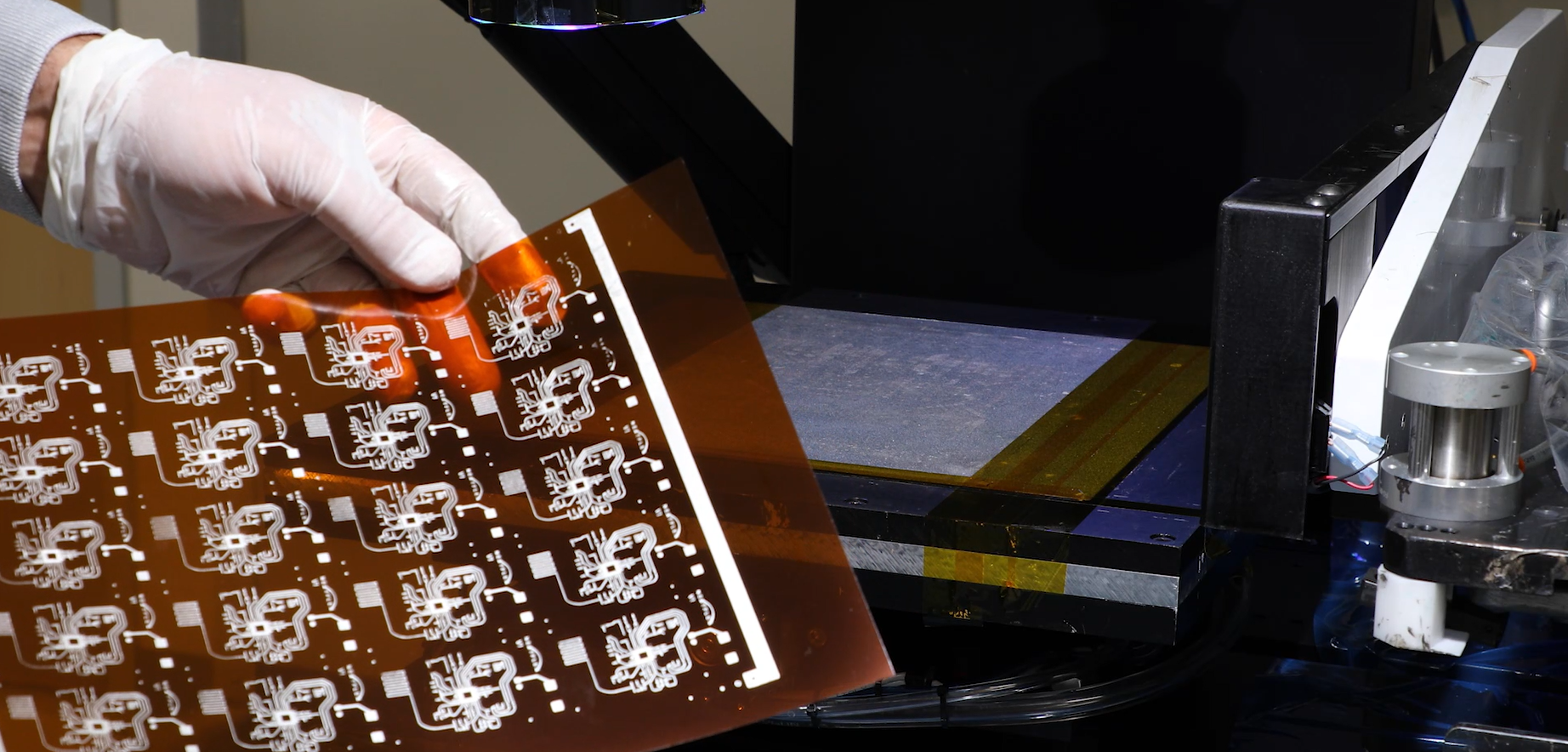

A: With prior involvement in various Nextflex agency driven projects, we have witnessed firsthand the potential impact of flexible electronics and hybrid manufacturing on various DoD programs and systems. The ability to leverage the NextFlex ecosystem to integrate these types of novel technologies into existing systems is a major draw for us. A lot of the systems we work on (UAVs, drones, PNT systems, munitions, and more) are becoming “smarter” and SWaP constraints are of paramount importance. Flexible electronics and hybrid manufacturing represent promising pathways for significant performance advancements in these domains. Moreover, the NextFlex ecosystem facilitates collaboration with leading experts and research groups at the forefront of this field, enabling us to leverage cutting-edge developments effectively.

Q: What is a key innovation that will enable widespread adoption of hybrid electronics and related technologies, and what application areas are you working in?

A: The key innovation lies in proving the reliability and compatibility of hybrid electronics with existing applications and hardware already in the field. Once proven , integrated hybrid electronic systems are poised for broader industry adoption. As a result, we are focusing on advancing the TRL/MRL of these hybrid electronics through iterative and rigorous testing while ensuring continuous intimate involvement of key innovators and developers during the early phase testing. This close-knit feedback aids in rapidly maturing hybrid electronics technology to match if not exceed Commercially Off the Shelf (COTS) components. One specific application being worked is the integration of “smart” deployable sensorized munitions. These sensors provide real-time updates to decision-makers without compromising payload space, integrating seamlessly within structural features or on the perimeter of conventional munitions.