Unlocking New Sensor Applications, Increasing Data Accuracy, and Untethering Patients

By Jason Marsh, Director of Technology, NextFlex

The number of new medical devices brought to market in the last 10 years is staggering. Consumers now have access to pulse oximeters, IR thermometers, automated heart rate monitors, and even active intervention devices such as Automated External Defibrillators (AEDs) that were previously only available to hospitals and medical professionals. The pace of device introduction is only increasing, and since better data requires better interfaces with humans, flexible hybrid electronics (FHE) are uniquely positioned to capitalize on growing opportunities for remote patient monitoring and home diagnostics—two major drivers of this growth.

Collecting patient data at regular intervals and more frequently than, say, an annual visit, can create what NextFlex refers to as a “personal baseline” for any given patient. What is important is not one’s heart rate or blood pressure compared to a global average that blends age, ethnicity, diet, altitude, and many other factors, but rather comparing it to what it was this morning, yesterday, last week, and last month. It is this perspective that often indicates a need for intervention.

We can compare this approach against how one would diagnose any complex system, and a human patient is significantly more complex than an automated factory or modern vehicle. It is telling that in 2018 we have better conditional data history on our automobiles than we have on ourselves. Today, the average length of a doctor visit in the US is less than 20 minutes and in the UK, it is less than eight minutes, according to a study by the Society of Internal Medicine. In this scenario, the doctor references data points which can be three to 18 months apart, and then bases a conclusion and recommendation upon a combination of other cases they have seen, their vague memory of your personal history, your anecdotal account, and their instinct. This is not a very scientific process. Improved personal baseline data is one very good way to improve the accuracy of future diagnoses.

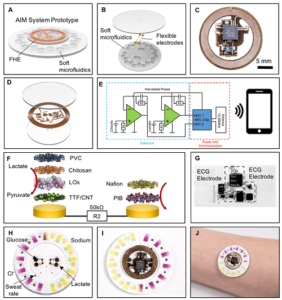

Since NextFlex was formed in 2015, a key focus has been on wearable and human-interfacing medical sensors and diagnostic devices. NextFlex’s first project call launched development work on many individual sensor technologies including oxygen sensing and oxygen delivery bandages led by Purdue University, Integra LifeSiences, and Western Michigan University; sensing and electric stimulation healing systems led by UC Berkeley and Jabil; a wireless EKG device led by GE Global Research and Binghamton University; and oral biomarker sensors led by PARC and UCSD. Each of these sensor technologies incorporates FHE in their design, delivering four distinct advantages for improving data collection from patients: new sensors, increased data accuracy, improved compliance, and continuous monitoring.

Four wireless EKG sensors ready for final assembly. (Photo by Global Research)

New sensor types are facilitated by the ability to integrate devices at low temperatures. Integration can happen in some cases below 100˚C, which allows manufacturers to include materials that would not survive traditional electronics assembly processes that typically occur at around 230˚C. This means that bio materials such as a bacteriophages or certain proteins can be integrated as part of the sensor system, opening the door to entirely new types of sensors.

Improved data accuracy can result from increased conformability that is enabled when interfaced with the flexible and stretchable substrates that FHE is well suited for. In many cases, the ability to conform to various patient skin types and profiles improves the application of the sensors, resulting in improved diagnostic accuracy.

In addition to improved skin surface conformability, the form factors made possible with FHE tend to being less obtrusive, less bulky, and more comfortable, thus increasing likelihood for the device to remain in place. Compliance improves and a continuous data stream from the patient is established. While early project calls at NextFlex and the Nano-Bio Manufacturing Consortium (NBMC) developed key sensors and measurement systems such as the sweat sensor patch, the pulse oximetry device, the wireless EKG, oxygen sensors, and others, it is the combination of datasets and the correlations within them that will yield the real breakthroughs. One example is the work presented by Dr. Christian Whitchurch of DTRA showing that when taken together, heart rate and body temperature can predict exposure to certain types of viruses much more accurately than either reading on its own.

In Project Call 3.0 three multi-sensor platform projects are underway. First, Epicore Biosystems is designing a sensor to measure sweat chemistry.

Sweat sensor system. (Image by Epicore Biosystems)

Second, Boeing is developing a multi-sensor applique system with mid-range RF connectivity and low power consumption designed for asset monitoring, yet capable of handling any sensor feeds used with it. A third project by GE Global Research and Binghamton University combines several clinical-grade medical sensors into a system, in reach of the vision of Oliver Astley, CTO of GE’s Mobile Digital Healthcare Division, to eliminate all wires on hospital patients, and to get the patient out of the hospital entirely and instead monitor them in the comfort of their home. These ideas drove NextFlex’s “FHE Impact on Health & Safety of the Future” workshop hosted at PARC last March.

The NextFlex team also saw an example first-hand at Mercy Virtual in Missouri last August, where nearly 300 care providers are monitoring three or more patients each from consoles in the digital health building. The program has been so successful that Mercy has been contracted by three other hospital chains to provide this same capability as a service.

Learnings reveal that patient recovery can move from the hospital to the home, while still collecting clinical-quality data throughout the recovery process; the patient recovers faster; and costs are reduced. This is the value proposition of FHE to enable this future through a suite of healthcare sensor systems now in development at NextFlex. We can develop a significant amount of the foundational technology to not only prove these devices possible, but manufacture them at the scale needed to make an impact and the organizations involved will likely see strong growth in these category-defining technologies.